Capabilities to meet your blade needs

B.A.P. manufactures many types of blades and edges for several industries including custom industrial, paper manufacturing, food processing, medical and surgical industry, handtools, hobby-related, graphic arts, hunting, packaging, and many others. We are committed to providing long-lasting, quality blades and edges.

We have over 40 years of expertise to produce a variety of shapes and edge configurations.

Our unmatched experience has allowed us the opportunity to partner with many companies -

large and small to develop blades and edges for processes that have revolutionized many industries.

As an ISO 9001 Certified company you can trust you will always receive

consistant blade manufacturing quality with B.A.P. Manufacturing.

Some of the applications include corrugated packaging material, mat cutting, paper cutting, plastic, food processing, rubber cutting, sign making, hobby/sport related, textile products, surgical and medical applications of many types.

Having less than 40 employees makes B.A.P. Manufacturing small, but nimble. B.A.P. can respond to changes quickly, whether in prototyping or production of specialty blades or edges. We can also serve in an advisory capacity to help you to determine materials and geometry best suited for your blade and edge needs and / or project at hand.

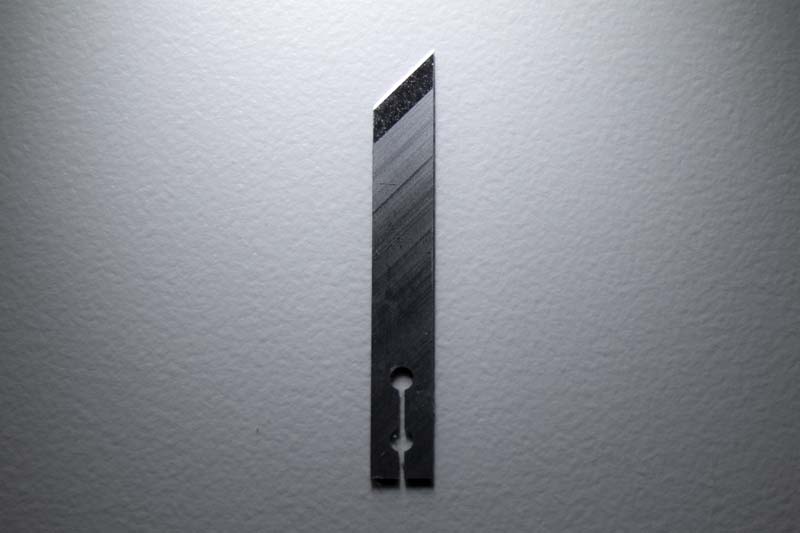

Specialty Blades

Specialty blades or edges often times begin with a drawing or sketch and then get prototyped to final production and manufacturing. If you dream it we can manufacture any blade at B.A.P.!

Standard Edges

Standard blades or edges are typically simple by design or a blade or edge that has been utilized in other applications and can be manufactured with quick production turn around.

Industry Blades

Industry blades are specific to the industry like surgical, food processing and hobby applications. These type of blades may have certain industry requirements to meet the needs.